| Payment Type: | L/C,T/T |

|---|---|

| Incoterm: | FOB,CFR,CIF,CIP |

| Min. Order: | 1 Set/Sets |

Basic Info

Model No.: MDO2900

Product Category: 3 Layers Co-extrusion Casting Film Machi

Product Structure: A/B/C

Product Thickness: 20um---100um

THICKNESS TOLERANCE: ≤±3%

Use Raw Material: Casting Level PP Material Etc

Maximum Extruding: About 600kg/h

Machine Speed: 300m/min (Maximum)

Running Speed:: 250m/min (Maximum)

Reel-up Diameter: ≤1000mm

Product Name: 3 Layers Co-extrusion CPP Line

Additional Info

Packaging: NAKED OR WOODEN PALET

Productivity: 290Kg/h

Brand: SUNNY

Transportation: Ocean

Place of Origin: CHINA

Supply Ability: 100 SETS PER YEAR

Certificate: CE

HS Code: 8477

Port: SHANTOU

Product Description

mdo cast film machine

Product Description:

MDO machine can use as an offline stretching film machine, or combined with small single screw extruder, small twin screw extruder, small triple screw extruder, and a small cast film machine, to form a MDO on-line cast film stretching machine.

Application:

Off-line film machine direction orientation.

Preparation of stretching film with different draw ratio.

New formula development.

Functional film preparation and processing research.

Film tensile performance test.

Optimization of film stretching parameters.

1. Basic Parameter

Machine body frame is made of structural steel and steel plate welded and assembly.

Pre-Heating roller φ320 x 2900 (by thermal oil): 4pcs

Tensile roller φ268 x 2900 (by thermal oil):2pcs

Fixiform roller φ320 x 2900 (by thermal oil):2pcs

Chill roller φ320 x 2900 (by water cooling):2pcs

Drive motor and drive system (SEW): 10units

φ150 aluminum idler roller (surface hardening treatment 700 degree): actuall matching

Conduction thermal oil heating system (CHINA)

MDO extension ratio: 2~3.5

MDO System

Features:

MDO is a proven technology which saves resources, improves film properties, and optimizes films for specific uses. SUNNY cast film line adopts MDO device, the process improves barrier properties and gives mono and coextruded films enhanced tensile strength and stiffness, better shrink properties, and increased gloss and transparency.

MDO machine can use as an offline stretching film machine, or combined with small single screw extruder, small twin screw extruder, small triple screw extruder, and a small cast film machine, to form a MDO on-line cast film machine.

Or you can choose the MDO casting integrated machine.

Rollers for preheating, stretching, annealing and cooling are all independently driven by servo motors.

The gaps between the rollers can be adjustedby moving the relevant roll horizontally.

Mold Temperature Controller and heat conduction oil is adopted to heat the rollers.

Single or multi stage draw sections.

Size customizable

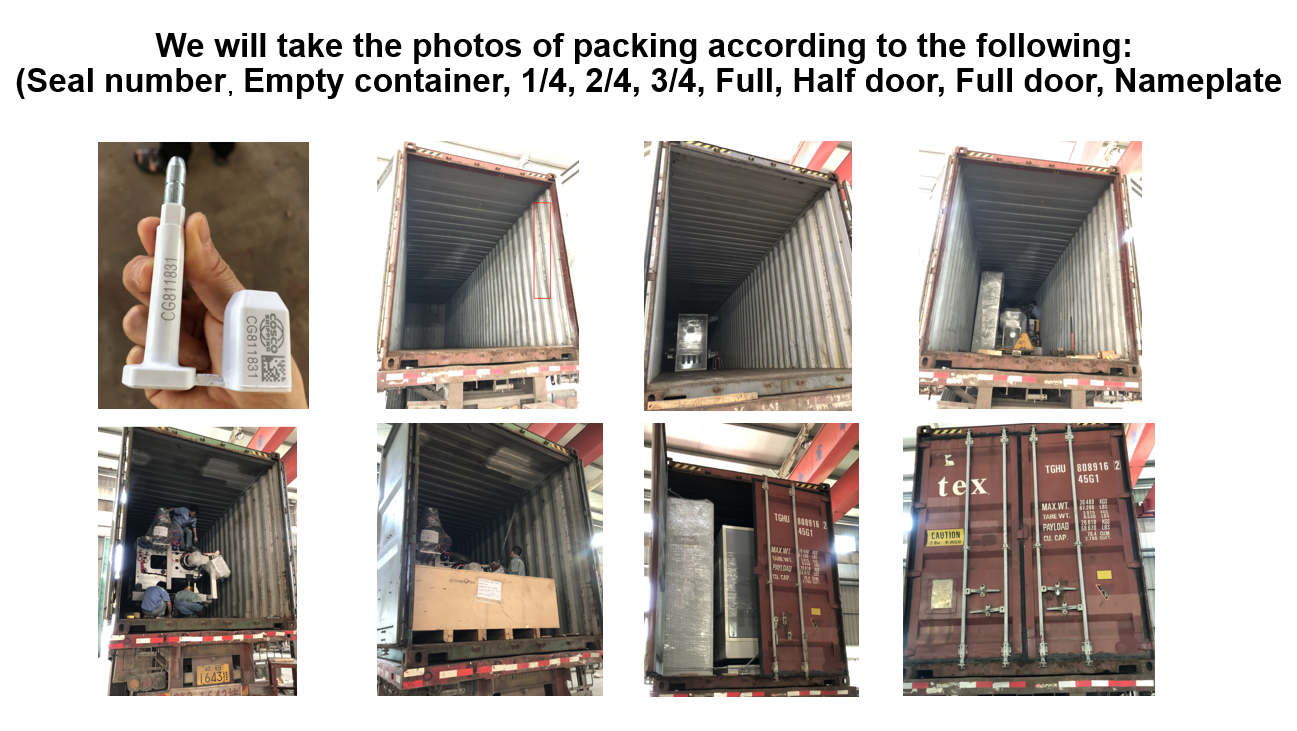

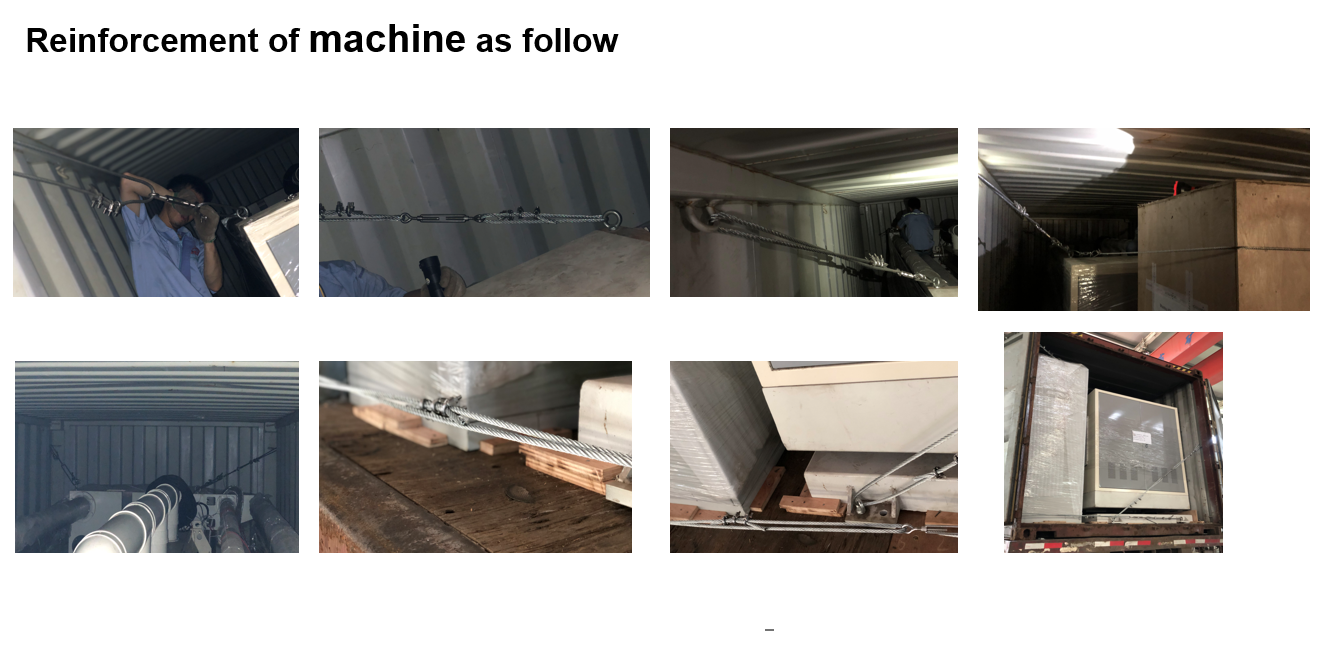

Packaging & Shipping

Our Service

Since 1998

After Sale-service

“Service is our business”

Our dedicated customer service team offers reliable assistance for our customers to ensure continuous operation of SUNNY machines at all times.

Non-stop telephone support

Remote control maintenance system

"Client Training Service"

Well-trained & experienced SUNNY service technicians

Innovative engineeering and the development help our customers to boost their productivity.

"Technical Service promise"

Providing Mechanical Electric, Electronic and Process set up.

Break down analyze

Always developed for you

Always specially optimised for your needs

Our strong design team can draw on extensive experience gained from the hundres of lines we have installed all over the world

Expertise Mechanical Engineer Department, Assembly Department, Electrical Department, Software Programming Department.

Top standard machinery can be provided, also all kinds of modifications can be customized according to customer specific requirements.

Company Information:

Sunny Machinery Factory is an integrated professional manufacturer to produce, design and sell Slitting, Rewinding, Laminating, Coating, and CPP or CPE 3 or multiple layers Cast Film machinery facilities with more than 20 years of experiences.

Our company has been developing and moving towards a greater competitive advantage by continuously improving technology and innovation.

All project will be serviced by our expertise in Mechanical Engineer Department, Assembly Department, Electrical Department, Software Programming Department, so we can offer our clients with our top standard machinery, also we can make all kinds of modifications according to customer specific requirements.

Our machineries are sold in many countries including India, Indonesia, Thailand, Vietnam, Brazil, Poland, Korea, Italy, Philippines, Singapore, Russia, Malaysia, Pakistan, Canada, Uzbekistan and so on.

© 2019 CHINA WAY. All Rights Reserved. SUNNY MACHINERY, Inc. All rights reserved. site map. sitemap.html