| Payment Type: | L/C,T/T |

|---|---|

| Incoterm: | FOB,CIF |

| Min. Order: | 1 Set/Sets |

| Delivery Time: | 180 Days |

Basic Info

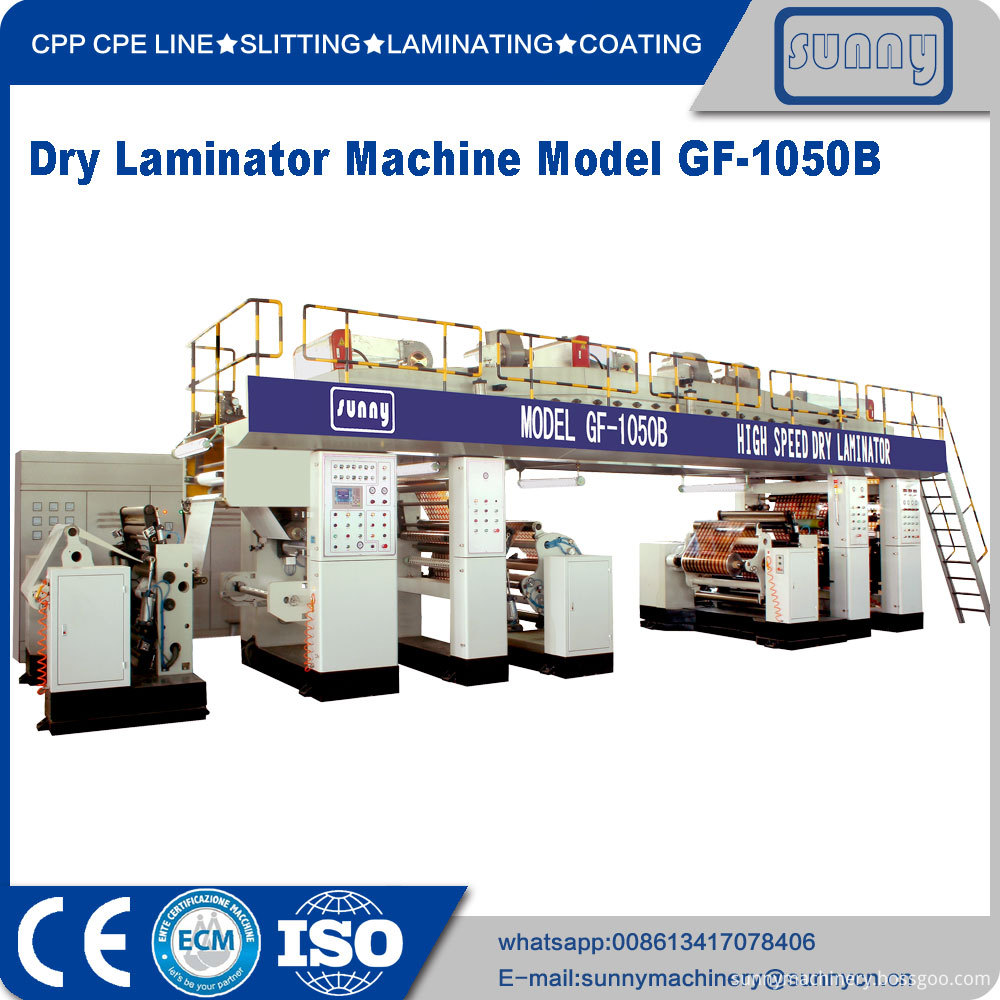

Model No.: GF1300

Laminating Type: Dry-method Laminating

.Laminating Material: BOPP 20-60μm; CPP 20-60μm; PE 30-60μm; Combination

Film Width:: 1300mm

Coating Glue Volume: By Anilox Roller Line Number And Glue Consistency

Machine Speed: Max.200m/min

Operation Speed: Max.180m/min

Guide Roller Width: 1400mm

1st Unwind Diameter: Max.φ1000mm

2nd Unwind Diameter: Max. φ1000mm

Ewind Diameter: Max.φ1000mm

Additional Info

Packaging: NAKED OR WOODEN PALET

Productivity: 180m/min

Brand: SUNNY

Transportation: Ocean

Place of Origin: CHINA

Supply Ability: 100 SETS PER YEAR

Certificate: CE

HS Code: 8477

Port: SHANTOU

Product Description

High Speed Solvent base Laminator Machine GF1300

High Speed Solvent base Laminator Machine is the elaborately manufactured product we referring to the advanced technology and experiences at domestic and abroad.

This machine is biaxially oriented film by coating gluing, dry solidification, and with other functional, heat sealing film laminating dedicated equipment, for BOPP 20-60μm; CPP 20-60μm; PE 30-60μm; PET 20-45um; NYLON 12-38um; Aluminium foil 7-12um Combination film 20-60μm, Glass paper 20-30μm. it is the key equipment in process for printing the laminating film product.

Main Technical Parameters

1). Laminating type: Dry-method laminating

2).Laminating material (adaptation material range):

BOPP 20-60μm; CPP 20-60μm; PE 30-60μm; PET 20-45um; NYLON 12-38um; Aluminium foil 7-12um Combination film 20-60μm, Glass paper 20-30μm

3). Film width: 1300mm

4). Coating glue type: gravure coating directly

5). Coating glue volume: by anilox roller line number and glue consistency control

6). Machine speed: Max.200m/min

7). Operation speed: Max.180m/min

8). Guide roller width: 1400mm

9). 1st unwind diameter: Max.φ1000mm

10). 2nd unwind diameter: Max. φ1000mm

11). Rewind diameter: Max.φ1000mm

Company Information:

Sunny Machinery Factory is an integrated professional manufacturer to produce, design and sell Slitting, Rewinding, Laminating, Coating, and CPP or CPE 3 or multiple layers Cast Film machinery facilities with more than 19 years of experiences.

Our company has been developing and moving towards a greater competitive advantage by continuously improving technology and innovation.

All project will be serviced by our expertise in Mechanical Engineer Department, Assembly Department, Electrical Department, Software Programming Department, so we can offer our clients with our top standard machinery, also we can make all kinds of modifications according to customer specific requirements.

Our machineries are sold in many countries including India, Indonesia, Thailand, Vietnam, Brazil, Poland, Korea, Italy, Philippines, Singapore, Russia, Malaysia, Pakistan and so on.

© 2019 CHINA WAY. All Rights Reserved. SUNNY MACHINERY, Inc. All rights reserved. site map. sitemap.html