| Unit Price: | 670000~1334000 USD |

|---|---|

| Min. Order: | 1 Set/Sets |

Basic Info

Model No.: CML3500

Applicable industry: Manufacturing Plant

Out-of-warranty service: Online Support, Spare Parts, Field Maintenance And Repair Service, Video Technical Support

Where to provide local services (in which countries are there overseas service outlets): Thailand, India, Indonesia

Showroom location (in which countries are there sample rooms overseas): Canada, Egypt, Italy, Viet Nam, Morocco, Thailand, India, Indonesia, Saudi Arabia, Malaysia, Uzbekistan

Video factory inspection: Provided

Mechanical test report: Provided

Marketing type: New Product 2020

Core component warranty period: 1 Year

Core components: Plc, Engine, Bearing, Gearbox, Motor, Pressure Vessel, Gear, Pump

status: New

Types of: Cleaner

use: Machinery &Amp; Hardware

degree of automation: Automatic

place of origin: China

warranty period: 1 Year

Core selling point: High Productivity

Product category: CPP

Product structure: A/B/C/D 20% 30% 30% 20%

Product thickness: 20µm---100µm

Thickness deviation: ≤±4%

Raw materials: extrusion grade PP, etc.

Output: ≧15 tons/day

Mechanical speed: Max.220m/min

Winding diameter: ≤φ800mm

Product width: ≤3200mm

Installed capacity: about 800KW

Additional Info

Packaging: Standard seaworthy packing (METAL PALLET+2MM MULTI-LAYER PE FOAM+MULTI-LAYER PAPER+1MM MULTI-LAYER STRETCH FILM )

Productivity: 14 -20 sets / year

Brand: SMF

Transportation: Ocean,Land

Place of Origin: CHINA

Supply Ability: 20 SETS PER YEAR

Certificate: CE CERTIFICATE

HS Code: 8477

Port: SHANTOU

Product Description

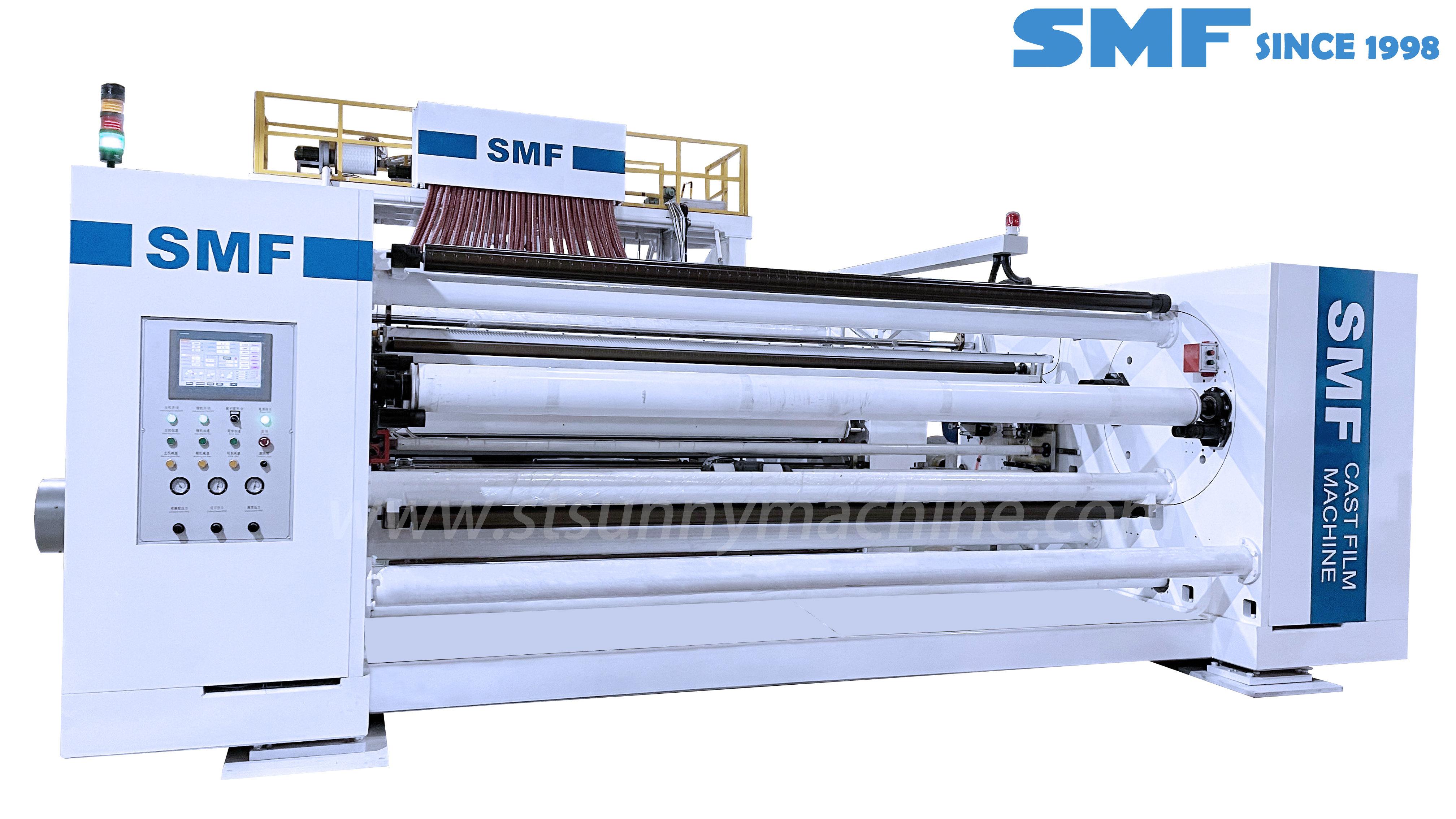

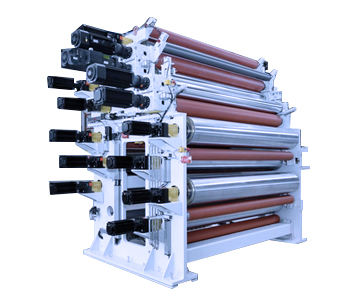

CPP film making machine 3500

1. Product Description:

CPP film making machine 3500 is primarily used in packaging industry for food, stuff and consumer goods. However, as a result of their special qualities, they are also used in technical products, medical products and as a mean of ensuring prefect surface protection. films produced in this way make an impressive impact due to their low gauge tolerances, high transparency, suitability for metallizing and printing.

2. Introduction:

3. Basic Composition

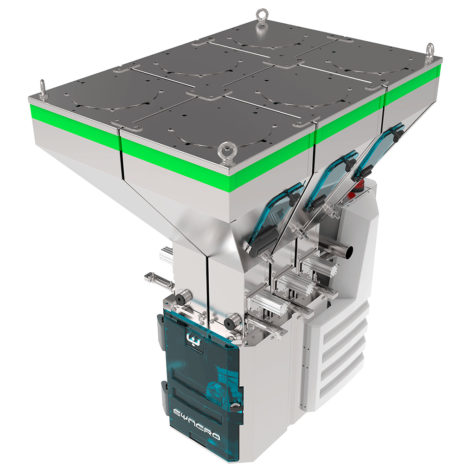

3.1. Auto. Feeding Blender Dosing System

It is important to ensure the efficient use in every film layer in consideration of that raw material be the main part of the cost for the production of cast films. Multi-components feeding system will be supply according to customer formula and requirements. Below two Feeding system for selection WINDING SYSTEM

3.2. Extruder System

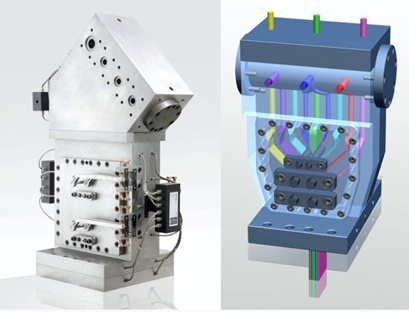

3.3. Connector, Distributor and T-Die Molding system

FLAT DIE

Multi Manifold Automatic Die

Cast film die series, including dies for producing CPP/CPE film, stretching film, breathable film, barrier film, etc.

●All Extruder barrels are heated using advanced heating system, thus retaining the heat in the barrel.

●Different diameter Extruder connector and stainless steel electric heater

●Multi-layer distributor (Depends on customer demand)

●Multi-layer Co-extrusion Automatic DIE (Depends on customer demand)

As a professional supplier of cast film lines, SMF relies exclusively on reliable partners for its feedblocks and flat dies.

- 3-layer feedblock with three extruders is standard for the production of CPP film, but there is also market demand for structures with five layers and four respectively five extruders.

- For barrier films there are no limits in terms of the number of layers. For example, 3-layer structures with three extruders are used for the minimum requirement, while maximum reach eleven layers are employed for special high-barrier structures.

- Co-extrusion flat dies with a hanger shape are able to incorporate fixed or variable internal deckling systems, which allows efficient variations of the net film width. Depending on the manufacturer, dies are either chrome- or nickel-plated, but in both cases automatic die control via thermal heated bolts is standard.

- In order to achieve better performance in terms of the individual layer distribution, multi-manifold laminating dies are sometimes recommended for the structures using polymers with large differences in melt viscosity or processing temperature.

Flat Hydraulic Filter

Large Area Hydraulic Screen Exchange

FeedBlock

We can supply our customers the most suitable feed block with the strongest practicality. In particular, the inlet and outlet dimension of feed block can be customized to connect directly with extruder and die, without requesting for transition part thus save the cost.

Technical Advantages

- Suitable for processing multilayer and multicolor coextrusion of polymers with similar flow rate and processing temperature.

- Conventional feed block structures including: insert type,mandril type,vane type. Besides,dedicated feed block for gradient film and hollow sheet.

- Accurate flow channel design assures perfect processing precision.

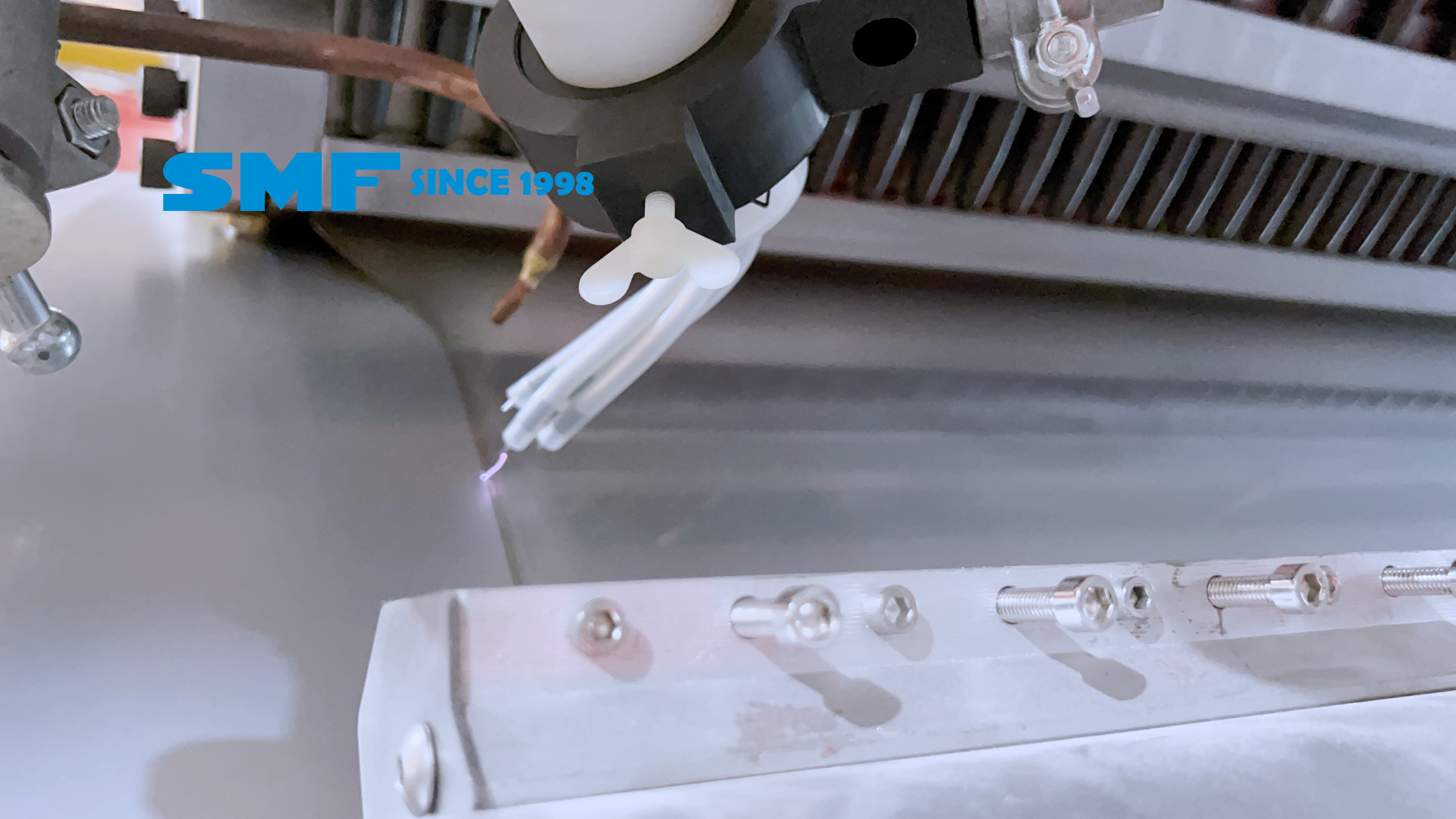

3.4. EDGE PINNING

The box, which is mounted directly on the die body, consists of two chambers. The pre-chamber extracts the air stream generated by the rotating chill roll, while the main chamber maintains low air pressure between the extruded film and the chill roll and prevents air entrapment. In addition, the length of the melt curtain can be adjusted before it touches the chill roll. Both chambers are equipped with separate, speed-controlled suction fans.

3.5. Casting Cooling System

3.6. Online Thickness Gauge Scanner System

3.7. Corona Treatment

3.8. Edge Trim Cutting

3.9. WINDING SYSTEM

4.0. MDO Unit

TYPICAL MODO FILM APPLICATIONS INCLUDE

1. PE Metalize film PE

2. CPP Metalize film CPP

3. PE breathable film PE

4. Barrier film

MDO Units consist of a stable, modular machine frame, including a preheating section, a stretching section and an annealing and cooling section. All the rolls are separately driven and temperature controlled. Well dimensioned film preheating and annealing sections are important with regard to mechanical properties and high production speeds.

© 2019 CHINA WAY. All Rights Reserved. SUNNY MACHINERY, Inc. All rights reserved. site map. sitemap.html